POE specializes in professional 3D print enclosure solutions and brings years of expertise in custom design, precision manufacturing, and delivering high-quality protective housings for electronic assemblies.

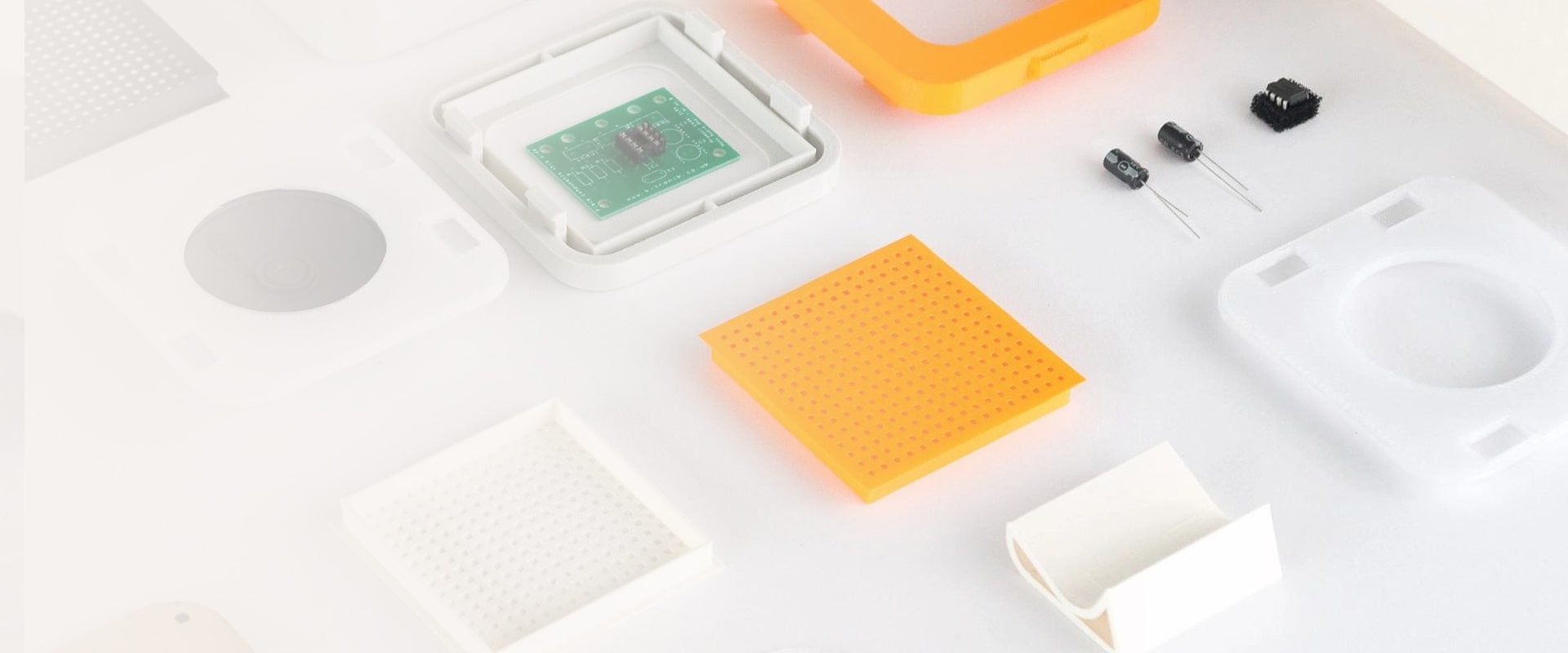

As a comprehensive PCB assembly partner, POE offers professional 3D-printed enclosure services to ensure complete protection and functionality for your electronic products. Our advanced 3D printing technology enables the creation of custom enclosures that fit your PCB assemblies precisely, safeguarding against environmental factors while maintaining both performance and aesthetics.

Designed to support businesses from startups to established enterprises, our 3D enclosure solutions combine precision engineering with cutting-edge technology to deliver housings tailored to your specifications, timeline, and budget.

POE delivers comprehensive 3D print enclosure solutions as part of our complete PCB/PCBA service offering. We utilize state-of-the-art 3D printing technology and premium materials to create custom protective housings that perfectly complement your electronic assemblies, ensuring optimal performance and professional presentation.

Tailored enclosure designs for your specific PCB requirements

PLA, ABS, PETG, TPU, and engineering-grade materials

High-resolution printing with tight tolerances

Built-in mounting points, cable management, and ventilation

Sanding, painting, and surface finishing options

Comprehensive testing and inspection protocols

POE provides a comprehensive one-stop solution for 3D print enclosure services, from design to delivery.

POE is committed to providing comprehensive PCB/PCBA services with professional 3D print enclosure solutions that meet the highest quality standards. We ensure timely delivery of precision-engineered enclosures while maintaining transparent communication throughout the design and manufacturing process. Our team provides rapid prototyping and scalable manufacturing processes for custom enclosures to achieve consistent quality and professional finished products.

Advanced 3D printing technology for superior enclosure quality.

Our state-of-the-art 3D printing equipment and premium materials ensure exceptional durability and precision for your custom enclosures. We utilize industrial-grade printers with high resolution capabilities to deliver enclosures that provide optimal protection while maintaining professional aesthetics and perfect fit for your PCB assemblies.

Comprehensive design and engineering support.

POE provides complete design assistance from initial concept to final production. Our experienced engineers work closely with you to create custom enclosures that meet your specific requirements, including proper ventilation, cable management, mounting solutions, and aesthetic preferences. We ensure every enclosure is optimized for both functionality and manufacturability.

Quality assurance and international standards compliance.

Operating under ISO 9001:2015 and ISO 13485:2016 certifications, we maintain strict quality control throughout the 3D printing process. Our materials comply with REACH, RoHS, and UL 94V0 standards, ensuring your enclosures meet international safety and environmental requirements for global market distribution.

REQUEST A FREE CONSULTATION

Fill in the form with vour requirements and ouantity unloan the relevant documents and we will provide you with a free quote right away!

For All Products Purchased From Us, If You Encounter Any Quality:

Offer "24/7 After-sales Support".

Before sending us the files, you can sign a NDA with us to ensure you can choose us with complete confidence.

Industrial, communication, and medical electronics

— POE PCB/PCBA Manufacturer (@poe_pcba) January 4, 2026

don’t forgive process gaps.

At POE, PCBA is built on

traceability, process control, and verification —

not speed at any cost.

Different industries.

One disciplined manufacturing standard.#PCBA #Electronics #IndustrialTech pic.twitter.com/hIlyO5cd4W

Since 1996, POE has become a globally renowned PCB company, providing small to medium volume PCB/ PCBA manufacturing services.